If you ever wondered how tiny gears in machines work in unity. You are bound to be a mechanical engineer!

Mechanical Engineering is the epitome of science and the heart of art.

It’s about building a mechanism that others can only imagine. But it isn’t a fairytale that is the twist!

India, the land of great engineers like Dr. A.P.J. Abdul Kalam and Dr. Kota Harinarayana, produces over 1.5 million engineering graduates every year (India Times).

So what’s the plot?

A report found that only 34% of engineering graduates were found job-ready.

This is an unimaginable scene. That is an industry where creativity, physics, art, and manufacturing move hand-in-hand.

Learners excel only in theoretical knowledge with no hands-on experience of the practical skills industry needs.

At GaugeHow, we believe that a degree isn’t an accomplishment. Effective skills with practical learning will make you shine and outperform others in this field.

Let’s discuss the key mechanical engineering skills 2025 every beginner must have.

1. Proficiency in Robotics and Automation

Perfection in Robotics and Automation is a must in 2026. It’s the process of designing, building, and operating machines in such a manner that they can perform operations automatically.

With no or little human intervention.

Good knowledge of coding, sensors, and systems helps engineers design with precision. It sparks innovation and smarter problem-solving.

These skills lead to advanced creations like automated cars, robots, and assembly lines. In short, they turn ideas into intelligent machines.

Market giants are undergoing major shifts. Companies like Amazon, Microsoft, TCS, Siemens, and Intel are leading this change.

Thousands of employees are being laid off worldwide. Key factors are the rise of:-

- AI

- Automation

- New Technology

- Robotics

2. Designing and Simulation

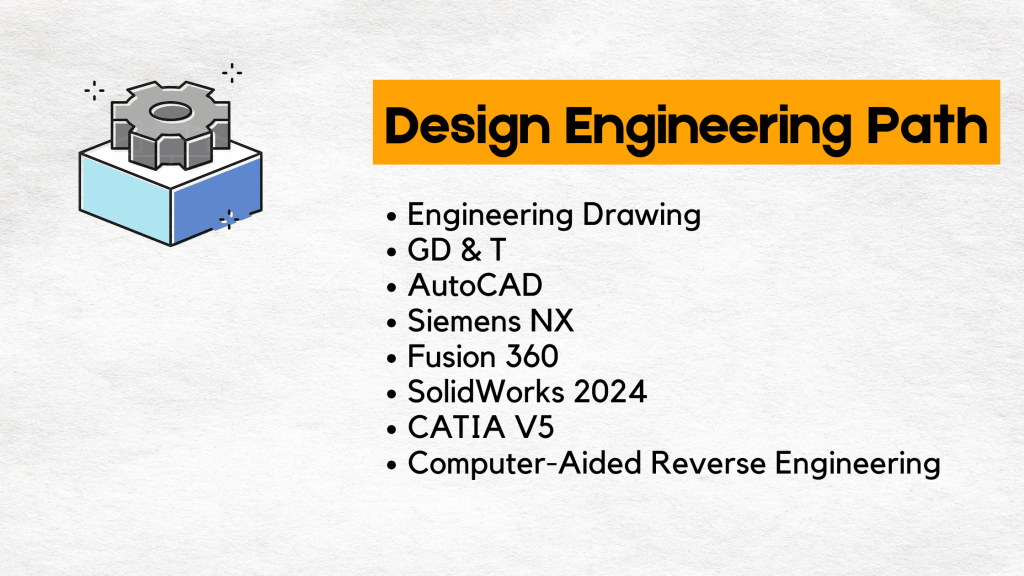

If you want to create, refine, and optimize designs, learning CAD and CAE principles is a must!

What is CAD?

CAD (Computer-Aided Design) is the divine weapon that every engineer, designer, and architect uses.

From Crafting 3D Models for components and assemblies. To compose data and reduce design errors – CAD is a Brahmastra! Some Popular CAD Software are:-

- Fusion 360

- CATIA V5

- SolidWorks

- AutoCAD

- Autodesk Inventor

How CAE assists CAC

Crafting 2D and 3D models is just a limited part. Computer-Aided Design (CAD) studies how structures work and move.

It helps fix design flaws and improve strength, heat, and performance.

It also lowers the cost and time of physical tests. Advantages of CAE:-

- Cost Reduction

- Virtual Testing

- Integrates well with CAD

- Improvise Product Quality

- Precision and Credibility

3. Mathematical and Reasoning Ability

Mechanical engineers are solution-oriented professionals.

With critical problem-solving ability and logical reasoning.

These engineers work on everything from design to improving heat systems.

They must be good at math and smart problem-solving.

Mastering numerical methods, calculus, geometry, algebra, and statistics is the core.

These skills boost technical knowledge and improve logical thinking and decision-making.

This encourages analytical thinking and defines the standards for upcoming mech developers.

4. Material Science and Lean Manufacturing

About 70% of design and manufacturing choices depend on material science. It’s the study of materials like metals, composites, and plastics.

Knowing a material’s properties and structure helps engineers understand its behavior.

It shows how materials perform in real-life situations.

This helps engineers create prototypes to see how machines will work in real life.

Material science and lean manufacturing cut costs by up to 20%. They also make products last about 35% longer.

From lightweight Aluminium in cars to strong composite materials in airplanes.

A good understanding helps engineers pick the right material for every machine part.

Prominent advantages of both are listed below:-

1. Cost Reduction – Eliminating waste by selecting affordable materials without compromising performance.

2. Consumer Satisfaction – Executing better products at cheaper rates.

3. High Product Quality – Helps engineers choose the right materials that make machines lighter, stronger, and durable.

4. Low Chances of Failure – Understanding of metal behavior prevents falls, cracks, and exhaust in machines.

5. Creation and Design – Supports innovation of advanced products such as alloys, composites, and smart materials.

5. Project Management Expertise

Working on complex and advanced projects needs highly qualified mechanical professionals.

Project management helps plan, organize, and control work. It ensures the project runs smoothly from start to finish.

It ensures smooth delivery of design, production, and quality standards. Smart decision-making, teamwork, and coordination are the key tools.

Why it Matters –

- Around 70% of projects fail globally due to poor planning, weak management, and broken goals (Standish Group — CHAOS reports).

- Project Management as a skill can earn you a million bucks!

- It helps companies save up to 30% in time and cost by reducing errors and rework.

- Skilled project managers boost success by 40-50% through teamwork and coordination.

6. Manufacturing and Prototyping

The most crucial process that begins with 3D designs and ends with full-scale production is known as manufacturing.

It’s about turning simple ideas into high-quality products. Using smart technology and creative innovation to make them better.

The 3D printing market is growing at 21% annually, expected to reach $44 billion by 2027 (3Dnatives).

A huge opportunity for Design engineers to innovate faster and build smarter. Smart manufacturing can improve product efficiency by 30-40%.

Mass manufacturing can only be concluded before proper Prototyping. Prototyping is about creating the first working model.

It ensures product quality check, durability, functionality, and performance. It can cut product development time up to 60%.

Benefits of Manufacturing and Prototyping

1. Innovation – Encourages the use of modern tools and technologies. This includes Industry 4.0, CNC machines, automation, and robotics.

2. Improved Product quality – Due to checking on testing and refining, it eliminates broken or weak products.

3. Sustainability and Scalability -Sustainability means using eco-friendly ways to make products. It helps reduce waste and keep the environment clean. Allowing industries to grow seamlessly from a small bunch to full-scale mass production.

4. Cost efficiency – Streamlined operations reduce expenses. And avoids expensive redesign later.

7. Thermodynamics

Thermodynamics is one of the core subjects of mechanical engineering. From engines to cooling systems, thermodynamics helps engineers design better machines.

It teaches how to save energy and make systems more efficient. It drives sustainable technologies that improve performance and reduce fuel consumption.

The Global HVAC industry is expected to reach $407.77 billion by 2030 (MarketsandMarkets).

Engineers in this field can earn 10-15% higher salaries in energy and manufacturing.

Core Skills Mechanical Engineers Should Develop.

1. Energy Systems – In-depth knowledge of the working of engines, turbines, compressors, and boilers.

2. Simulation Tools – Use of technical tools like ANSYS, SolidWorks, Autodesk CFD, and Siemens to optimize performance.

3. Heat Transfer Concepts – Good understanding of convection, conduction, and radiation.

4. Logical Thinking using Equations – Applying formulas of Heat transfer and Ideal gas law.

Conclusion

Mechanical engineering isn’t just about studying theories. It’s about building machines that power smart manufacturing.. Automation, AI, Robotics, and Smart Manufacturing are redefining the space.

Engineers have to stay ahead of the competition by gaining hands-on experience on live projects. And learning the skills that the real industry needs!

At GaugeHow, we inspire engineers to transform from learners to innovators. With expert-led courses in CAD, Material Science, Robotics, Thermodynamics, and Project Management.

We help engineers become confident, independent professionals. Ready to get high-paying jobs and lead the future of technology and design.

Also Read: AutoCAD for Mechanical Engineers: Step-by-Step Learning Guide

FAQs

1. “Which coding languages should a mechanical engineer learn in 2026?”

If you ask me, start with Python — it’s everywhere (data analysis, controls, automation).

Add MATLAB for control systems and simulation, and pick up C/C++ if you’ll work with embedded systems or robotics. For CAD automation, learn some scripting (e.g., Python for Fusion360 or macros for SolidWorks).

2. “How do I demonstrate hands-on skills when I only have classroom projects?”

Build a tiny portfolio: one or two well-documented projects (CAD model → prototype → test). Use low-cost tools: Arduino/Raspberry Pi for controls, a cheap 3D-printed prototype, and a short video + GitHub or Google Drive with diagrams, BOM, and test results.

Recruiters love a polished case study that shows process and outcomes.

3. “Which CAD/CAE tool should I learn first to get hired quickly?”

For manufacturing and product design roles, SolidWorks and Fusion 360 are excellent starters.

If you’re targeting aerospace/automotive, invest time in CATIA and ANSYS for advanced simulation.

The trick is to show both modeling and simulation (stress/thermal) on at least one project.

4. “Is robotics really a must-learn or just ‘nice to have’?”

It’s increasingly essential. Even if you don’t become a robotics engineer, automation concepts (sensors, actuators, control loops) are being embedded across manufacturing and product roles.

Learn the basics — sensors, PID control, and one robot framework — and you’ll be far more competitive.

5. “How should I learn project management as a mechanical engineer?”

Start practical: learn Agile basics, WBS creation, Gantt scheduling, and risk registers. Get comfortable with one PM tool (MS Project, Asana, ClickUp).

A short cert (e.g., CAPM or a practical course on Agile for engineers) plus a real project where you act as the lead will make your resume stand out.