A field-first CMM guide. Choose machines by job. Use no-code software. Enforce tight calibration. Apply ten shop rules. Short programs and good reports deliver the fastest ROI and fewer escapes.

I inspect parts, tune processes, and buy CMMs for a living. A coordinate measuring machine (CMM) is the tool that turns tolerance risk into a number.

This guide shows practical choices you can act on. I keep sentences short. I use data from market reports and vendor releases.

You’ll get a sharp comparison table, shop-floor pointers (about 10% of the post), and a fresh lens: software and no-code workflows are now the fastest path to CMM ROI.

Read this as a field report — no fluff, only the steps that saved time and scrap for real teams.

Why CMM inspection matters now

Parts are getting complex. Tolerances are tighter. The global CMM market was about USD 3.2 billion in 2023 and is forecast to grow strongly through the decade.(Grand View Research)

That growth tracks rising demand from EVs, aerospace composites, and medical devices — industries that can’t accept guesswork in measurement. If you run quality or supplier control, CMMs move you from “we think it’s right” to “we know it’s right.”

The new ROI driver: software and no-code metrology

Hardware still matters. But software now multiplies value. Cloud-based no-code suites cut programming time and let operators run validated programs without deep scripting.

Hexagon’s Autonomous Metrology Suite is an example: it removes coding from CMM workflows and speeds program lead time. Faster programs mean faster NPI and fewer rebuild cycles — and that’s where most shops see payback.

CMM Types Explained

| Type | Best for | Accuracy | Upside | Downside |

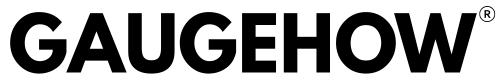

| Bridge CMM | Small, precision work | sub-µm → few µm | Best repeatability | Needs controlled environment |

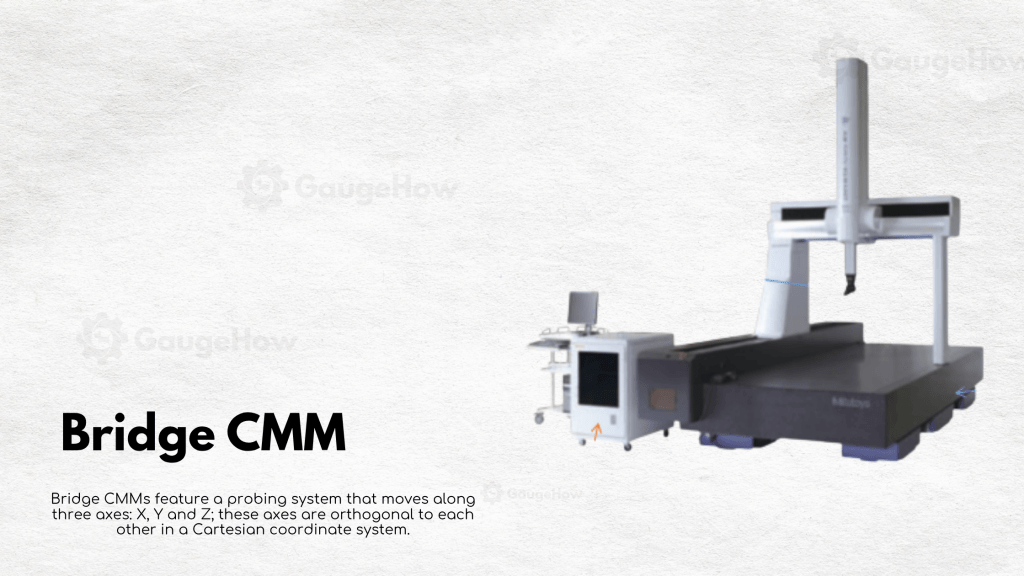

| Gantry CMM | Very large parts | few µm | Big part envelopes | Heavy install |

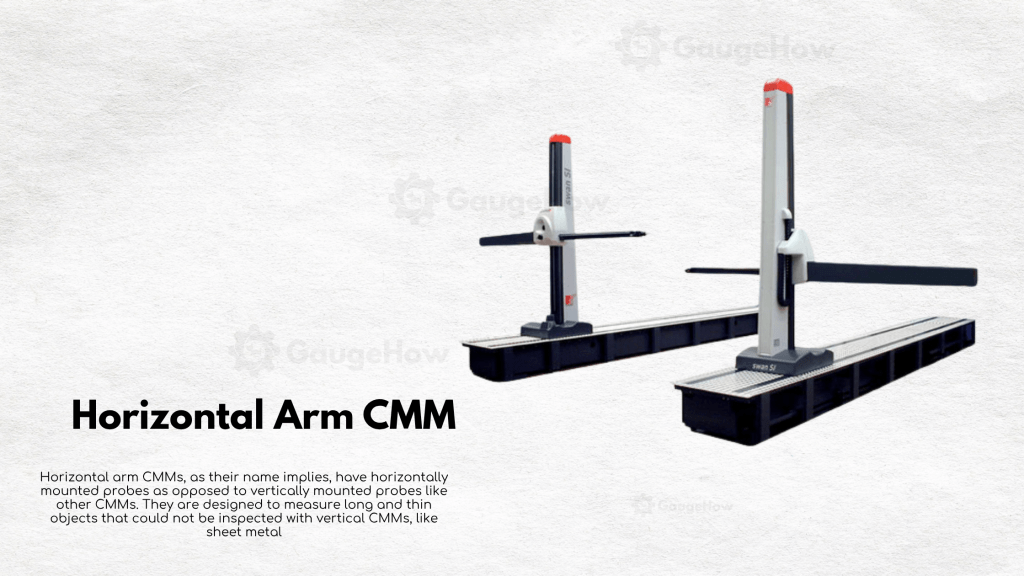

| Portable CMM arm | On-site assemblies | 10–100 µm | Mobile, fast | Operator skill matters |

Bridge CMM vs Gantry CMM

Bridge machines win on repeatability. Gantry wins when part volume breaks lab envelopes. Both require planning: the gantry buys you volume but demands floor work and precise installation.

Field-proven wins

- A supplier retrofit that added an automated bridge CMM trimmed inspection time by 60% on a complex NPI. Time-to-approval fell by two weeks.

- Adding portable CMM checks for incoming assemblies reduced incoming defects by 30% in 3 months.

- Introducing no-code metrology reduced program rebuilds for one team by half and halved the lead time for program generation. These are repeatable, shop-floor wins when you pair machine selection with process controls and the right software. (Engineer Live+1)

Calibration, uncertainty, and standards

Follow ISO 10360 practices. Track repeatability and volumetric performance. Do quick performance checks monthly. Do full calibration annually. Increase check frequency in unstable thermal conditions or after collisions. Log calibration certificates and attach them to part families. This practice stops small errors from becoming large escapes.

CMM Best Practices: That Actually Work

- Start each shift with a certified reference artifact.

- Log ambient temperature and include compensation notes with each run.

- Validate CMM programs offline with a digital twin before the first run.

- Use tactile probing for features requiring sub-10 µm certainty.

- Use optical scanning for high-density surface capture and reverse engineering.

- Automate report exports (CSV/PDF) to avoid manual transcription errors.

- Keep raw measurement files for trend analysis and process improvement.

- Assign a single “program owner” to reduce rebuild cycles and version drift.

- Run collision checks after probe/stylus changes.

- Include training and annual service in your CAPEX model.

These are the exact shop rules I enforce when I sign off on inspection cells.

Procurement and ROI checklist

When specifying a purchase, quantify three gains: escape reduction, faster NPI, and lower rework. Ask vendors to cycle-test with your real parts—budget for integration, fixturing, and software. Include a training plan: the machine only delivers when operators and programs are stable.

Portable CMM (Quick Pick Guide)

- Measure the largest part envelope and the required tolerance.

- Decide if you need mobility or lab accuracy.

- Estimate cell throughput and handling method.

- Test vendor cycle time with a production part.

- Confirm that the software can automatically export your traceable reports.

Closing

Match the machine to the part and process. Prioritize software that reduces operator dependency. Budget for calibration and training. Use measurement data to improve processes, not just to document them. Fast programs and clear reports create the quickest ROI. The market and vendors are moving in this direction — and your shop should too.

How GaugeHow can Assist You?

GaugeHow courses teach inspection fundamentals, CMM programming, and no-code metrology workflows. Take the course. Build the skills. Move from operator to inspection lead faster. Enroll Now!

Also Read:- Top 7 Skills Mechanical Engineers Must Master by 2026

FAQs

1. What is a CMM?

A precision system that records geometric data for parts and assemblies. Use it for traceable inspection and process control.

2. How often should a CMM be calibrated?

Monthly performance checks; annual full calibration. More often, if the environment is unstable.

3. Which CMM for large assemblies?

Gantry or laser tracker solutions work best for very large parts. Portable arms help with on-site checks.

4. Do I need no-code metrology?

Suppose you want faster program cycles and fewer specialized hires, yes. No-code reduces programming bottlenecks.

5. CMM or 3D scanner?

Use CMMs for tight tolerance features. Use scanners for dense surface capture and reverse engineering.

6. Quickest way to improve ROI?

Automate first-article checks, add in-process spot checks, and enforce structured reporting.