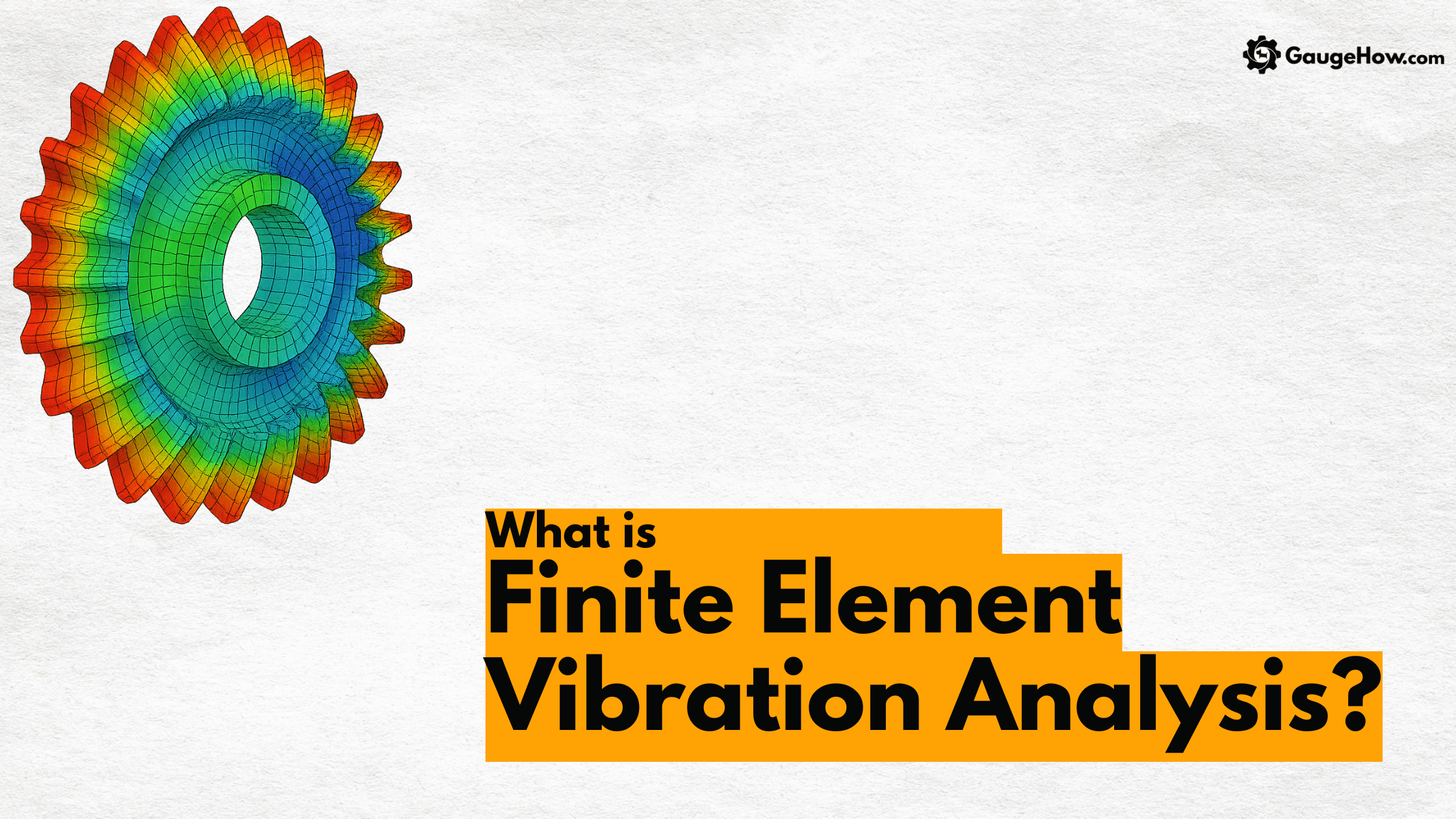

Finite Element Analysis speeds validation, cuts prototypes, and finds failures early. I mix market data, case studies, and hands-on rules so you get practical, field-tested FEA methods.

I’ve run FEA on both surviving and failing parts. Finite element analysis is no longer optional.

It is the method that turns a design guess into a tested decision. In this post, I blend market signals, peer-reviewed case work, and vendor best practices. You’ll get short, usable steps to run FEA software with intent.

I will show where demand sits, what FEA solves fast, and where it breaks down. Read this if you want crisp, practical guidance backed by data and my hands-on experience.

Why finite element analysis matters right now

Manufacturers push for lighter, safer, faster parts. That raises dependence on finite element analysis for stress, thermal, and dynamic checks. Firms are shifting budget from physical prototypes to virtual validation.

This trend shows in market reports and vendor results (IMARC Group; Mordor Intelligence). FEA for mechanical engineers cuts cycles, cost, and risk when used correctly.

FEA as a product-risk lever, not a feature

View finite element analysis as a form of risk capital. Apply it where one failure costs time, recall, or lives: landing gear, battery packs, crash structures. Early FEA use saves weeks of prototyping and thousands in rework. Studies on EV battery thermal cases show simulation prevents thermal runaway and speeds development (ScienceDirect).

Quick market snapshot

| Metric | Value / Year | Source |

| FEA market size (global) | USD 6.3B (2024) | IMARC Group |

| FEA software market estimate | USD 6.9B (2025) | Mordor Intelligence |

| Simulation software market | USD 19.95B (2024) | MarketsandMarkets |

| Example — ANSYS revenue | USD 2.54B (FY 2024) | ANSYS (investor release) |

How I use FEA software on real projects — practical steps

- I start with a 1D or 2D analytic check to set scale and expectations.

- I prepared a CAD model for simulation. I remove tiny features that do not affect load paths.

- I pick element types by physics: solids for stress, shells for thin skins, and coupled solids+CFD for batteries.

- I mesh with intent: refine near stress raisers, keep coarse mesh elsewhere. Then I run a mesh-independence test.

- I validate with a simple test (strain gauge, modal tap). I trust the model only after validation.

- I convert validated cases into parametric sweeps or DOE to find robust solutions.

Common mistakes engineers make with finite element analysis

- Over-meshing: many elements do not fix wrong BCs or poor element quality.

- Wrong boundary conditions: unrealistic supports give false safety.

- Ignoring material nonlinearities in plastic or composite designs.

- Treating vendor defaults as gospel — solver settings matter for contact and large deformation.

- Skipping verification: no convergence means no trust.

Compact FEA checklist

- Define the objective: safety margin, fatigue life, natural frequency, or thermal cap.

- Choose the physics: structural, thermal, coupled thermal-structural, or explicit crash.

- Simplify geometry: keep features that influence local stress; remove the rest.

- Use real material data: stress-strain curves beat handbook yield values.

- Mesh rule: start coarse → refine locally → run convergence until key results change <2–5%.

- Model contact with small gaps and friction when needed.

- Enable nonlinearity when loads change paths: plasticity, large deflection, contact algorithms.

- Validate at least one bench or field test for each critical component.

- Document input decks, solver versions, and assumptions.

- Post-process: check reaction forces and energy balance to spot solver issues.

Real-world examples that prove the value of finite element analysis

- EV battery thermal management — FEA + CFD workflows find hot spots and guide coolant channel design. This reduces gradients and lowers the risk of thermal runaway. Vendor papers and peer reviews show clear safety gains.

- Automotive crashworthiness — explicit solvers like LS-DYNA predict occupant metrics. OEMs often halve the number of physical crash tests after strong simulation verification.

- Aircraft landing gear & wingbox — high-fidelity FEA with fatigue and damage tolerance enables weight reduction and life certification. Case studies show shorter design cycles and cost savings.

When not to trust FEA — and how to fix it

- Unknown material behavior (e.g., heat-treat). Fix: test the material first.

- Speculative boundary conditions (unknown supports). Fix: measure service conditions or run sensitivity studies.

- Solver energy balance errors or unstable contact. Fix: review solver settings, time step, and mesh quality.

My practical rules for credible FEA outcomes

- Rule 1: The solver solves the math you give it — not the real problem you meant. Check units, BCs, and loads.

- Rule 2: Use mesh-independence as a gate. Don’t accept numbers until they converge.

- Rule 3: Validate one experiment per new physics or material.

- Rule 4: Automate parametric sweeps. Designs that survive a sweep are robust.

Tools, training, and where demand sits

If you build courses or articles, target practical queries: FEA tutorial, FEA software, ANSYS tutorial, Abaqus tutorial, FEA for mechanical engineers. Users searching for these want how-tos and downloads, not only theory. Use Semrush or Keyword Planner to confirm volumes before ad buys.

Conclusion

I’ve built and validated FEA models for frames, battery packs, and composite skins. The lesson is simple: simulation pays when used with discipline. Do early checks, choose correct physics, validate once, then run sweeps. Market signals show growing simulation spend. Create content that teaches FEA well. That converts readers into learners and buyers.

I teach practical FEA and I’ve built courses that skip fluff. Our mechanical engineering courses online focus on hands-on FEA, validation, and project work. Learn tools you will use on the job.

Join GaugeHow to build confidence and speed in your designs.

Enroll today and start the next module.

FAQs

1. What level is the course for?

Our courses suit junior engineers to experienced designers. Each path has clear learning outcomes.

2. Which software do you teach?

We cover ANSYS, Abaqus, and common pre/post tools. We show workflows, not only buttons.

3. Are there hands-on projects?

Yes. Every course includes real projects and validation steps you can repeat in the lab.

4. How long does a course take?

Most full modules run 6–8 weeks at part-time pace. Self-study options let you go faster.

5. Do I get a certificate?

Yes. You receive a GaugeHow certificate after passing the project and quiz requirements.

6. What prerequisites do I need?

Basic mechanics and CAD experience. We include refresher material if you need it.